Mechanical switch contact

Versatile fields of application

Small size

Easy to connect

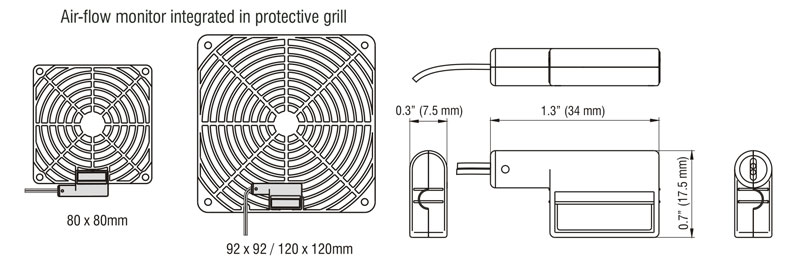

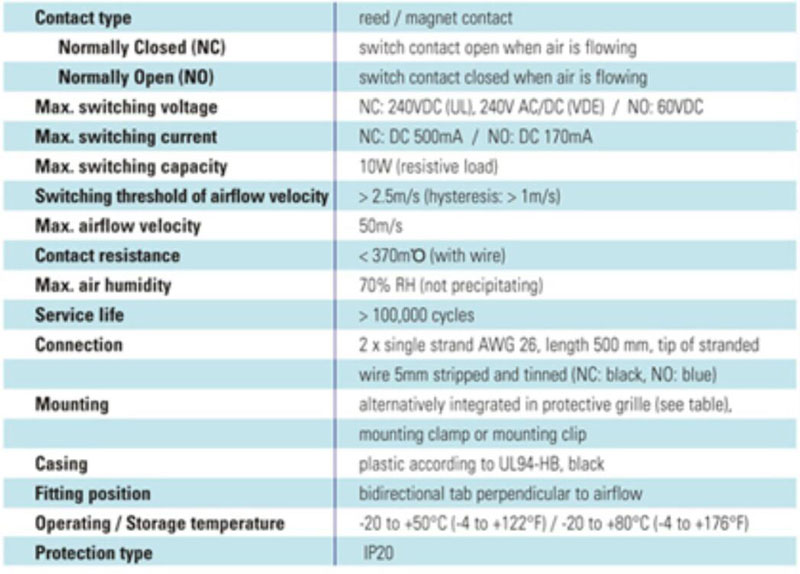

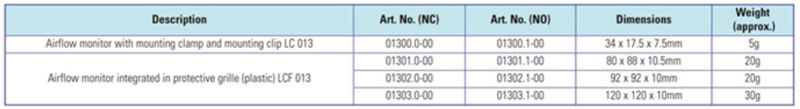

The airflow monitor (NC/NO) is designed to indicate the loss of air movement of a fan or filter fan.The contact detects the loss of air movement caused by fan failure or blocked filter media regardless of direction of air. it’s simple mechanical operation makes it a viable alternative to electronic monitoring systems.

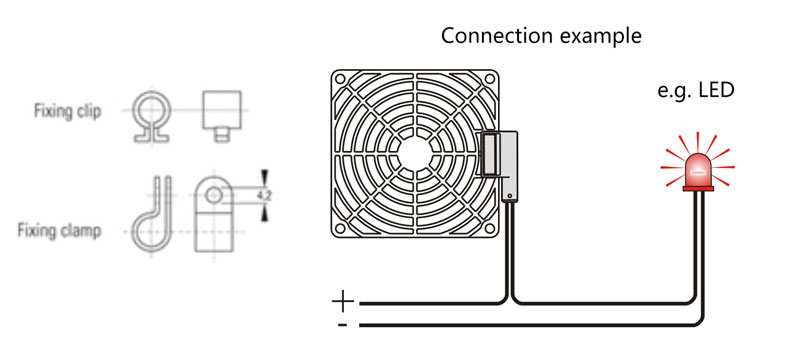

The LC013 is used as a signal contact to monitor fans or filter fans in stationary.self-contained Protection Class l enclosures. It can be connected to monitoring systems with remote control or can directly switch alarm devices, such as LED's or signal lamps. Loads with capacities exceeding the indicated switching capacity must be switched via a relay.e.g. our electronic relay SM 010.The airflow monitor with NC contact closes upon loss of air movement,i.e. it indicates fan failure (e.g. red signal lamp\. The N0 contact closes when fan is in operation and serves as optical function display (e.g. green signal lamp).

Note: The product of switching voltage and switching current must not exceed 10W. The max. voltage and max. Current must not be exceeded,not even short-term (voltage/current peaks).The resulting voltage and current peaks of inductive or capacitive loads must be restricted by a contact protection circuit.

1. The airflow monitor must not be installed in the impact range of permanent mages or ferrous metals as the built-in permanent magnet ill move unintentionally and consequently can not move in dependence with the air flow.

2. A suitable distance from electromagnetic fields, e.g. generated by transformers, motors, etc., must be maintained as otherwise the contact may switch incorrectly with the frequency of the power supply. Interferences must be checked with an oscillograph and the mounting position of the airflow monitor should be adjusted if necessary.

3.Avoid installing the airflow monitors in areas where air pockets or turbulence can be expected.

4.Ambient air with a high dust content should be avoided.

As there are many different conditions of use, suitability of this product must be assessed by the end user in its final application.

GET A QUOTE