Use and structure characteristic

The BK series engine bed control transformer (here after refers to as transformer) to be suitable the voltage of 500V frequency 50-60 Hzelectrical circuit. Usually serves as powersupply for engine bed control electric appliance or the partial flare and indicating lamp.

- 1.The surrounding air temperature is from-5℃ to 40℃, the average value is not exceed 35℃ of 24 hows;

- 2.The installation site elevation does not surpass 2000m;

- 3.The atmospheric relative humidity will less than 50 percent,once the ambient air temperature is +40℃, at lower temperatures can have relatively high temperature, the largest wetlands on the average humidity is 90%, while the average monthly minimum temperature is +25℃, and taking into account the temperature changes due to occurin the surface of Rich Products.

Model and meaning

Matters needing attention

- 1.Before purchase, first estimates the electric appliance aggregate capacity which you use, and select the suitable capacity transformer, guarantees the instantaneous starting will not burn the transformer.

- 2.This transformer strictly according to national related standard design production. When you use the multi-windings ( multi-controlvoltage ) transformer, the capacity should according to the ratio-voltage corresponding increase transformer capacity, in order to avoid burns out the transformer.

- 3.Before the installment, should examine the parameters carefully to sure whether them meet your requirement, after confirmed unmistakable, only then installs use.

- 4.(After the circular telegram work, the transformer core and the coil will heat but the temperature will not exceed 80℃ ) it is the normal phenomenon, if the temperature rise up 80°℃, even belch smoke, please cut down the power source and inspect the electric appliance capacity which you using.

- 5.In the transportation, please avoid colliding as far as possible, please sure not to be affected with damp, when use, please note maintains, protects the transformer service life.

BK transformers are mainly used in various industrial and electrical equipment, and their main applications include:

- Voltage Regulation: BK transformers can convert high voltage to low voltage, or vice versa, to meet the voltage requirements of different equipment.

- Power Adjustment: They can adjust the output power to match the input power, which is particularly important for equipment such as motors and lighting fixtures that require specific power levels.

- Protection Function: BK transformers have certain protective functions, such as limiting the output current to protect equipment from overload damage when the input voltage is too high.

- Isolation: They can isolate the high-voltage side from the low-voltage side, preventing electrical interference and the risk of electric shock, making them suitable for applications with high safety requirements like medical and laboratory settings.

- Energy Saving: By adjusting the output voltage and power, BK transformers can allocate and utilize electrical resources efficiently, reducing energy consumption.

- Machine Tool Control: BK transformers are commonly used in the electrical systems of machine tools and other mechanical equipment as a power source for control circuits, lighting circuits, and signal circuits.

- Power Supply: They are also commonly used as a power source for electronic equipment, providing a stable and safe voltage output.

- Local Lighting: BK transformers are suitable for local lighting power supplies, such as machine tool work lights.

- Indicator Light Power: In machine tool control electronics, BK transformers are used for the power supply of indicator lights.

- Signal Power: They can also be used for the power supply of signal lights and indicator lights.

BK transformers play an important role in industrial control and power conversion due to their small size, safe and reliable wiring, high protection level, and good performance.

When selecting a BK transformer, consider the following key technical specifications:

- Rated Capacity (VA): Choose a transformer capacity that matches the actual load, with a long-term working load rate not exceeding 85% to ensure economical operation of the transformer.

- Rated Voltage (input/output): Select the appropriate input and output voltages based on the actual power grid voltage and the voltage required by the equipment. Common input voltages include 380V and 220V, and output voltages include 220V, 36V, 24V, 12V, 6V, etc.

- Frequency: The transformer is designed for AC power sources at 50Hz or 60Hz.

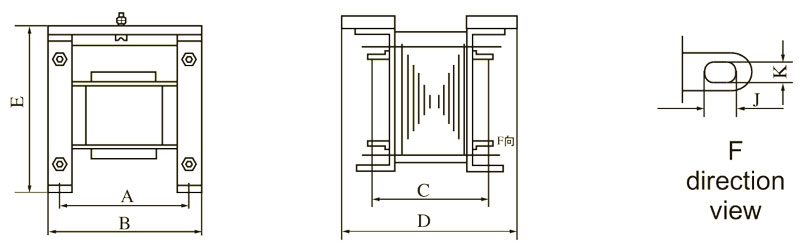

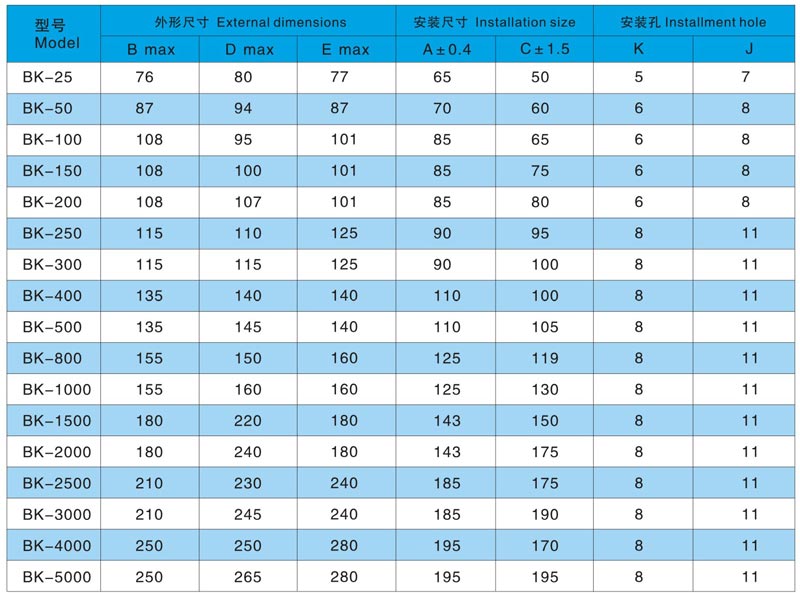

- Dimensions and Mounting Size: Consider the physical size and installation space of the transformer to ensure it fits existing equipment or systems.

- Cooling Method: Choose the cooling method based on the actual application environment and load conditions, such as natural convection or forced air cooling.

- Protection Level: Select the appropriate protection level based on the installation environment, with outdoor environments potentially requiring a higher level of protection.

- Insulation Level: Consider the transformer's insulating materials and insulation level to suit different environmental and temperature requirements.

- Load Characteristics: Choose a transformer based on load characteristics, such as some transformers having strong load and overvoltage capabilities.

- Special Functions: Consider requirements for isolation, load adjustment functions, etc.

- Certification and Standards: Ensure the transformer complies with relevant industry standards and certifications, such as JB/T 5555, Q/DLX 361, etc.

When selecting a model, it is recommended to consult with a professional electrical engineer or the manufacturer's technical support to ensure the correctness of the selection.