Main features

· 200A Contact switching capability

· One set of normally open contacts forms

· Coil power consumption is:22~29W Min~Max

· Application Scope:Oil pump startup, Battery truck, Electric forklift,

Electric winch, Electric vehicle, Excavator, Automobile air conditioner.

On off control of DC power supply systems.

· Product features:Small volume, high breaking capacity, sealing protection,

and can adapt to harsh service environment

· Product certification: CE

Application

Matters needing attention

1.When installing the contactor, the tightening torque of the main circuit wiring screw nut is 8~10N.m;

Control circuit wiring screw nut tightening torque 1~1.5N.m.

2.The driving circuit power of the product coil must be greater than or equal to the product coil power,

Otherwise the cutting capacity of the product will be reduced.

3.The voltage continuously applied to the coil shall not exceed the maximum allowable voltage.

Otherwise, the abnormal heating of the coil will shorten the life of the insulation layer.

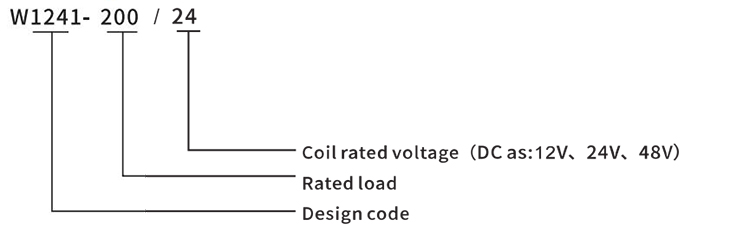

Example:W1241-200/24;Indicates: a group of normally open contacts, sealed type with current of 200A and coil voltage of 24VDC contactor

Example:W1241-200/24;Indicates: a group of normally open contacts, sealed type with current of 200A and coil voltage of 24VDC contactor

|

Model |

W1241-200/□ |

|

Contact form |

One set of normally open |

|

Contact load |

200A |

|

Insulation resistance |

Min. 100MΩ at 500VDC |

|

Dielectric Strength |

1000VAC 50 HZ/60 HZ (1 minute) Leakage current less than 1mA |

|

Instantaneous maximum current |

600A ,≤1S |

|

Pull in time(ms) |

≤30 |

|

Release time(ms) |

≤50 |

|

Pull-in voltage (DC V) |

10~70% US |

|

Release voltage (DC V) |

5~40% US |

|

Operating ambient temperature |

-25℃~+55℃ |

|

Mechanical life |

≥300,000 second |

|

Degree of protection |

IP67 |

|

Working system |

Short term working system |

|

Vibration |

(10~200)Hz acceleration ≤3.5g |

|

To attack |

(60) Times / minute acceleration 6g |

Coil parameters

|

Model |

Coil voltage (V) |

Coil operating voltage(V) |

Pull-in voltage(V) |

Release voltage(V) |

Starting current(A) |

Power waste(W) |

|

W1241-200/□ |

12 |

0.85US~1.1US |

≤70% |

5~40% |

≤2.5 |

22~29 |

|

24 |

≤1 |

22~29 |

||||

|

48 |

≤0.6 |

22~29 |

GET A QUOTE