> Clean production environment

> Full automatic testing with various tests

> Standardized production process with trained workers

> Low failure ratio and 24-month warranty

> Strong R&D and engineering support

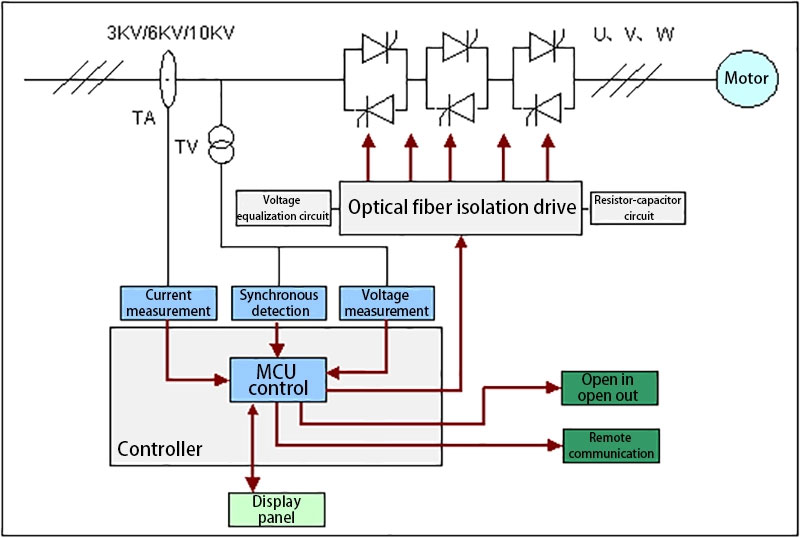

Soft starting device is the high voltage ac motor starting equipment, its main composition is connected into the power between the charged with motor and three instead of parallel thyristor components and electronic control unit. WSTRHV series high voltage solid-state soft starting device is composed of multiple thyristor series parallel, by controlling the thyristor trigger Angle to control the size of the output voltage, can satisfy the motor starting process in different voltage and current requirements. In the process of motor starting, WSTRHV series high voltage solid soft starting device according to the preset curve starting, increase the voltage of the motor, the motor smooth acceleration, so as to reduce motor starting on the grid, and connected equipment electrical and mechanical shock. When the motor starts up to normal speed, the bypass vacuum contactor or circuit breaker is connected, and the motor starts to finish. During the operation of the motor, the soft starting device continues to monitor the motor, measuring the electric current, voltage and all kinds of fault protection in real time.

1) Overvoltage protection, undervoltage protection: voltage exceeds the set voltage range, the protection action and send a signal.

2) Over-current protection: start or run the process of excessive current, more than set the current value, protection action and send a signal.

3) Current imbalance: three-phase current imbalance will lead to motor jitter and heat, three-phase current unbalance value exceeds the set range, the protection action concurrent signal.

4) Start-up time: When the motor starts longer than the set time limit, the protection action is signaled.

5) Overload protection: motor running process, the occurrence of overload, the protection action and signal.

6) Underload protection: During operation of the motor, underload or loss occurs, protection action is generated.

2. Measurement functions

1) Voltage measurement: measurement of power line voltage

2) Current measurement: motor A, B, C three-phase current detection.

3. Communication Interface

1) Display communication: display panel selection touch screen, RS232 communication.

2) External communication: external device and controller communication, RS485 communication, standard MODBUS protocol.

4. Open and out

1) The amount of 8 points, optoelectronic isolation, no power into.

2) Out of 7 points, contact capacity of 10A / 250VAC, no power out.

5. The user interface

1) Touch-screen display, a touch operation.

2) Transfer switch and operation button: straight up / soft start, the cabinet / remote two switch, start, stop, direct start, emergency stop four buttons.

3) Status indicator: power, ready, start / soft stop, bypass / run, fault, bypass points 6 lights.

Note: The above is the standard configuration, special circumstances can be adjusted according to user needs.

|

Model |

Voltage level |

Rated current |

Cabinet size |

||

|

(kV) |

(A) |

H(mm) |

W(mm) |

D(mm) |

|

|

WSTRHV-350/3 |

3 |

80 |

2300 |

1000 |

1500 |

|

WSTRHV-650/3 |

3 |

160 |

2300 |

1000 |

1500 |

|

WSTRHV-900/3 |

3 |

220 |

2300 |

1250 |

1500 |

|

WSTRHV-1150/3 |

3 |

280 |

2300 |

1250 |

1500 |

|

WSTRHV-1500/3 |

3 |

360 |

2300 |

1250 |

1500 |

|

WSTRHV-1500(the above) |

3 |

>360 |

Booked |

||

|

WSTRHV-700/6 |

6 |

80 |

2300 |

1000 |

1500 |

|

WSTRHV-1300/6 |

6 |

160 |

2300 |

1000 |

1500 |

|

WSTRHV-1800/6 |

6 |

220 |

2300 |

1000 |

1500 |

|

WSTRHV-2300/6 |

6 |

280 |

2300 |

1000 |

1500 |

|

WSTRHV-3150/6 |

6 |

360 |

2300 |

1000 |

1500 |

|

WSTRHV-3000/6(the above) |

6 |

>360 |

Booked |

||

|

WSTRHV-850/10 |

10 |

60 |

2300 |

1000 |

1500 |

|

WSTRHV-1100/10 |

10 |

80 |

2300 |

1000 |

1500 |

|

WSTRHV-2000/10 |

10 |

140 |

2300 |

1000 |

1500 |

|

WSTRHV-2200/10 |

10 |

160 |

2300 |

1000 |

1500 |

|

WSTRHV-2750/10 |

10 |

200 |

2300 |

1000 |

1500 |

|

WSTRHV-3050/10 |

10 |

220 |

2300 |

1000 |

1500 |

|

WSTRHV-3800/10 |

10 |

280 |

2300 |

1000 |

1500 |

|

WSTRHV-5000/10 |

10 |

360 |

2300 |

1000 |

1500 |

|

WSTRHV-5000/3(the above) |

10 |

>360 |

Booked |

||

|

Category |

Explanation |

| AC voltage |

AC3kV/6kV/10kV,±10%-15% |

|

Load type |

Three - phase high - voltage AC induction motor, synchronous |

|

Frequency |

50Hz/60Hz ± 2Hz |

|

Main circuit composition |

3kV,12SCRS;6kV,18SCRS;10kV,30SCRS |

|

Transient overvoltage protection |

Pressure protection and resistance absorption network |

|

Cooling method |

Natural cooling |

|

Control method |

Three-wire |

|

Environmental conditions |

Ambient temperature: -10-40 deg.] C, altitude: not more than 2000 m, the relative humidity: not more than 85% |

When the soft start device detects the external start command, after the microprocessor detects the synchronization signal, the main circuit thyristor phase angle trigger control, and gradually increase the motor side of the current and voltage, so smooth start the motor. In this process, the RC RC absorber absorbs the peak voltage at the time of thyristor reverse turn-off; the voltage-controlled thyristor voltage ensures that each thyristor voltage in the series circuit is equal. Fiber triggering ensures electrical isolation between the controller and the high voltage thyristor, while ensuring that the trigger signal is not subject to electromagnetic interference.

GET A QUOTE